New Additive Manufacturing Center Gears Up to Support SLU Researchers, St. Louis Region

Through a grant from the Saint Louis University Research Institute, the new SLU Center for Additive Manufacturing (SLU-CAM) will offer the University community and St. Louis region opportunities to advance innovation across a wide range of diverse disciplines by offering access to the latest additive manufacturing technology.

Additive manufacturing, or 3D printing, is transforming fields like engineering and manufacturing around the world. Globally, the market for additive manufacturing equipment is growing at a rate of more than 15 percent annually by some estimates, and is expected to reach $34B by 2024, according to a Frost and Sullivan Report and Global Newswise.

Through SLU-CAM, students, researchers as well as outside organizations and business partners can utilize the center's printers now for projects ranging from class finals to real-world prototyping.

New Technology to Support Innovative Research

Two newly-acquired state-of-the-art Stratasys printers - a Stratasys Fortus 450MC high performance material large-build-volume FDM printer and Stratasys J735 multi-color, multi-durometer, polyjet printer - are already in place, one in a temporary location in Shannon Hall, and the other in McDonnell Douglas Hall.

In addition to the University's investment in technology, support staff have also been put in place to run and maintain its equipment. The center's staff members will also provide technical support and guidance on additive manufacturing to researchers and other center users.

While printers' current locations are temporary, the center will be permanently housed in SLU’s new Interdisciplinary Science and Engineering (ISE) Building, which will open by the 2020 fall semester.

Years of Experience and Expertise to Serve Users

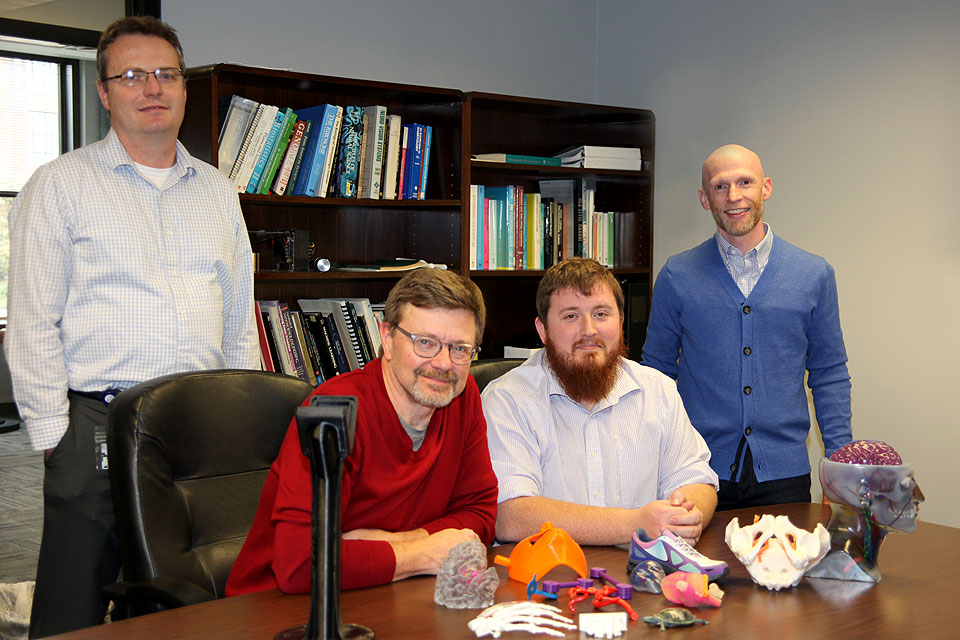

SLU-CAM is led by an interdisciplinary team of University researchers with deep experience with 3D-printing.

The Center Team

- Scott Sell, Ph.D., associate professor and program coordinator in biomedical engineering

- Scott Martin, Ph.D., professor and chair of the Department of Chemistry

- Andy Hall, D.Sc., assistant professor in biomedical engineering and director of SLU-CAM

- Andre Castiaux, Ph.D., postdoctoral researcher in the Department of Chemistry

The investigators have been involved in a number of 3D printing related research projects, which will be helped by the addition of these new printers.

One example project is the design and production of custom microfluidic devices, used to study the complex interactions of various cell types in both healthy and diseased states. The technology is also used to print custom tissue molds, derived from CT scans, which are then filled with a nano-scale scaffold conducive to cell growth, for the purpose of filling tissue gaps, such as those encountered in cleft palate patients.

Another use is printing radiopaque CT phantoms for the purpose of optimizing CT scanning protocols, which are used in prostate artery embolization.

The center's leadership team has identified more than 30 other current SLU faculty members whose work aligns with the center's goals and who may be able to use it as a resource to advance research and student-learning, Andy Hall, D.Sc., SLU-CAM director said. Researchers in Parks College of Engineering, Aviation and Technology, Department of Chemistry and Department of Biology in the College of Arts and Sciences; Richard A. Chaifetz School of Business; Doisy College of Health Sciences; and the School of Medicine could potentially use the center, Hall said.

"With the two printers we have acquired, we hope to be able to address a broad range of research and other academic applications," Hall said. "We can print in full color. We can print objects of variable durometer (rigidity). We can print with biocompatible materials that can be sterilized, and can print with very strong materials, such as carbon fiber impregnated nylon. Print detail and size can range from hundreds of microns to tens of centimeters."

"And for technologies that we don’t have in house, our plan is to develop a network of supplies for more exotic AM technologies," he continued. "In my own lab experience, 3D printing has helped accelerate (and reduce cost on) most every project I have. I believe we can bring similar value to other labs as well, and we are anxious to engage in those discussions."

Teaching the Next Generation of SLU, St. Louis Innovators

The center builds on the University's mission to form technically proficient and socially responsible innovators and leaders through impactful learning and leading-edge research.

“SLU's Center for Additive Manufacturing allows our faculty and students to not only think of big ideas, but also to design and build solutions to some of society’s greatest challenges," Michelle Sabick, Ph.D, dean of Parks College of Engineering, Aviation and Technology, said.

In addition to supporting University-specific research initiatives, the center, as one of the most expansive of its kind in the St. Louis area, aims to make SLU as a regional leader in additive manufacturing.

“St. Louis is quickly becoming a hub for tech startups and modern makerspaces,” Scott Sell, Ph.D., SLU-CAM leadership team member, said. “We believe SLU’s Center for Additive Manufacturing offers some unique capabilities, that have not been locally available to SLU or St. Louis tech community users.”

Building Bridges to Bolster Opportunity

While a few local organizations are using large-scale 3D printing in their daily functions, SLU-CAM is uniquely positioned to become a resource to the broader multi-state area.

The Center has already received support from both local corporations and the tech start-up community. Partners including Boeing, National Geospatial-Intelligence Agency (NGA), MADE – Maker Space, Cambridge Innovation Center (CIC) and BioSTL have expressed interest in using the center's services or are in preparations to begin work with SLU-CAM.

In addition to its work with St. Louis entrepreneurs and innovators, SLU-CAM offers students, particularly those in STEM disciplines, a way to get hands on experience with cutting-edge technologies to further their educations.

"Our team feels strongly that SLU-CAM will move research forward at SLU and in the St. Louis area," Scott Martin, Ph.D., a member of the center's leadership team, said. " From our interactions with on-campus users and with potential corporate partners it is clear that the St. Louis region will benefit from the expertise and capabilities in the center."

"I think there are also some interesting educational activities that will come from this center, with our students gaining cutting edge experience in the rapidly evolving field of 3D printing," Martin continued.

Work with the Center

Three categories of users will be able to use the center including:

- Researchers who are thoroughly trained on the systems and/or who have extensive experience with using this technology. These researchers, generally SLU faculty members or affiliated researchers, will have direct access to the center's printers.

- Students and less experienced researchers will be able to submit their CAD file or files (part design specifications) to the center team. Center staff members will print the object and notify the user when the object is complete and ready for use.

- Users who wish to utilize the center staff's expertise in developing the CAD file or files should contact the center to receive assistance. Center staff members will work directly with the user, will develop the CAD file, will print the object and will notify the user when the object is complete and ready for use.

The center is still developing its charge policy. The policy is expected to include introductory reduced fees for new users during a set period to be determined by the center's leadership team.

Prospective center users and researchers should contact should contact Andy Hall, D. Sc., Andre Castiaux, Ph.D., or the center with questions or for more information.

Founded in 1818, Saint Louis University is one of the nation’s oldest and most prestigious Catholic institutions. Rooted in Jesuit values and its pioneering history as the first university west of the Mississippi River, SLU offers nearly 13,000 students a rigorous, transformative education of the whole person. At the core of the University’s diverse community of scholars is SLU’s service-focused mission, which challenges and prepares students to make the world a better, more just place.

Written by Amelia Flood, University Marketing and Communications